Tongue and Groove Flooring

Tongue and Groove Flooring

Tongue & groove was an innovation of the seventeenth century. As dovetail joints, tongue and groove it allows artisans joining together parts of a whole without the use of nails. The process is still used today. Hardwood planks are fitted together to create a beautiful floor. Although not all wood floor is made of tongue and groove boards, and probably will remain, the predominant form of soil found in homes around the world.

Installation

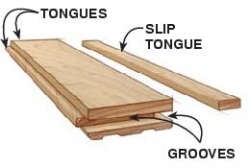

Floor tongue and groove can be constructed from many kinds of woods. The most popular woods used are oak, maple, cherry and Brazilian bamboo. The wood is planned on tables measuring 3 inches wide up to 5 inches wide. With tongue and groove floor, each board is set to the next. One side is the tongue, a nose rounded along the table. On the other side is the slot in which the tongue is equipped.

Types

Floor tongue and groove can be solid or engineered wood. Solid wood floors are constructed as a solid piece of wood. It is layers of wood. A soft wood joins a hardwood and then sandwiched between hardwood and plywood base. The plywood base is moisture resistant and provides stability. Softwood creates a buffer zone.

Benefits

Tongued floor allows tables fit closely together, creating a smooth finish and safer seams. Solid wood flooring tongue and groove can have a very long shelf life; It can be sanded and varnished. This is not true for wood, such as plywood is too thin to allow subsequent sanding. Although it has quite the life of solid wood, wood is easier to install.

Reach TimberFloorRestoreMalaysia.com for more information